- Home Page

- Company Profile

-

Our Products

- Steam Boiler

- Rice Husk Fired Steam Boiler

- Industrial Steam Boiler

- Husk Fired Boiler

- Wood Fired Boiler

- Oil Fired Steam Boiler

- Oil Fired Boiler

- Reverse Flow Steam Boiler

- Package Boiler

- Fire Steam Boilers

- SIB Steam Boiler

- Smoke tube Package Steam Boiler

- Solid Fuel Fired 10 TPH Water Wall Membrane Panel Steam Boiler

- Coconut Shell Fired 5000 Kg-hr Steam Boiler

- Nutshell Fired 4 TPH Fully Wetback Steam Boiler

- 2 TPH Electric Steam Boiler

- Coal Fired 3 TPH Fully Wetback Steam Boiler

- Thermic Fluid Heater

- Heat Exchanger

- Bag Filter

- Industrial Boiler

- Solid Fuel Boiler

- Industrial Steam Boiler

- Boiler

- FBC Boilers

- Wood Fired Steam Boilers

- Glass Smoking Pipes

- Oil Fired Steam Boiler

- Coconut Shell Fired 3000 Kg-hr Steam Boiler

- Oil And Gas Fired 500-1000 Kg-hr 3 Pass Wet Back Boiler IBR Approved

- Oil & Gas Fired 3000 Kg-hr Fully Wetback Steam Boiler IBR Approved

- Oil & Gas Fired 8000 Kg-hr Fully Wetback Steam Boiler IBR Approved

- Oil & Gas Fired 50 kg-hr Coil Type Steam Boiler Non-IBR

- Oil Fired Heaters

- Pulse Jet Bag Filter

- Steam Boiler

- Contact Us

Oil Fired Steam Boiler

1200000.00 INR/Unit

Product Details:

- Pressure 10.54 kg/cm (g) (approx.)

- Output Steam

- Capacity 500 kg/hr to 4000 kg/hr

- Voltage 415 V

- Life Span 15-20 Years

- Temperature Up to 180C

- Condition New

- Click to view more

X

Oil Fired Steam Boiler Price And Quantity

- 1 , , Unit

- 1200000.00 INR/Unit

- 50 mm to 100 mm

- 50 Hz

- Floor Mounted

- Meets National Norms

- Digital/LCD Display

- Varies as per model

- Rugged and Corrosion Resistant

- Glass Wool/Min. Wool Insulated

- Multi-level Safety Protection

- Industrial Commercial Process Heating

- Semi-Automatic/Automatic

Oil Fired Steam Boiler Product Specifications

- Mild Steel

- 10.54 kg/cm (g) (approx.)

- Up to 180C

- Generates Steam by Oil Combustion

- New

- 85% approx.

- Horizontal

- Oil Fired

- Boiler

- 8-30 kg/hr (Depending on model)

- 500 kg/hr to 4000 kg/hr

- Steam

- 415 V

- 15-20 Years

- 3100 mm x 1500 mm x 2100 mm

- 50 mm to 100 mm

- 50 Hz

- Floor Mounted

- Meets National Norms

- Digital/LCD Display

- Varies as per model

- Rugged and Corrosion Resistant

- Glass Wool/Min. Wool Insulated

- Multi-level Safety Protection

- Industrial Commercial Process Heating

- Semi-Automatic/Automatic

Oil Fired Steam Boiler Trade Information

- 5 , , Unit Per Month

- 60 Days

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Kerala, Nagaland, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

Product Description

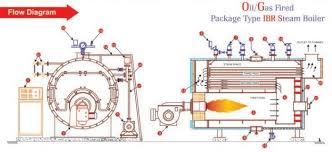

Oil & Gas Fired Steam Boiler that we provide to our customers is widely used in the chemicals industry for process heating, jet drying in the textiles industry, lamination unit in the packaging industry, press molding in the rubber industry, seasoning kiln in the wood industry. This is widely demanded by our numerous customers for its high efficiency and seamless functioning. Further, it is perfect to be sued in various applications as it can function using a number of different fuel source like diesel,furnace oil, natural gas and LPG. We provide this Oil & Gas Fired Steam Boiler at market leading rates with various easy payment options.

Versatile Performance for Industrial Applications

The oil fired steam boiler is tailored for various industrial and commercial settings, offering flexible capacity options and efficient steam generation. Its robust structure and dependable safety mechanisms make it suitable for process heating in manufacturing, chemical plants, and other demanding industries, ensuring smooth operation and consistent output.

Advanced Safety and Control Features

Equipped with multi-level safety protection and a modern digital/LCD display, this boiler prioritizes operational security and user-friendly monitoring. The automated or semi-automatic control functions help maintain precise operation, while its compliance with national emission norms supports environmentally responsible performance.

FAQs of Oil Fired Steam Boiler:

Q: How does the oil fired steam boiler generate steam?

A: The boiler generates steam by combusting oil to heat water held within its insulated chamber. The heat converts the water into steam, which is then distributed through the process heating system for industrial or commercial applications.Q: What safety features are integrated into this boiler?

A: This steam boiler is equipped with multi-level safety protection systems, including pressure and temperature sensors, emergency shutoffs, and digital control panels to ensure safe and reliable operation during all phases of use.Q: When should I opt for the automatic versus semi-automatic model?

A: Opt for the automatic model when you require minimal manual intervention and enhanced precision in controls, especially in large-scale or continuous operations. The semi-automatic version is suited for facilities where some manual adjustments are feasible and operational requirements are moderate.Q: Where is the ideal installation location for this steam boiler?

A: This floor-mounted boiler is best installed in industrial or commercial facilities with ample space, proper ventilation, and adherence to safety regulations. It should be situated where regular maintenance and operational access are convenient.Q: What maintenance is involved in the operation process?

A: Routine maintenance includes inspecting fuel lines, checking control panel alerts, cleaning the combustion chamber, verifying pressure and temperature settings, and ensuring water quality. Scheduled servicing extends the systems lifespan and optimizes efficiency.Q: What are the main benefits of using this oil fired steam boiler?

A: Benefits include high heat efficiency (about 85%), robust and corrosion-resistant construction, automated safety systems, compliance with emission standards, flexible capacities, and a long operational life span of 1520 years, making it a cost-effective solution for industrial process heating requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese