- Home Page

- Company Profile

-

Our Products

- Steam Boiler

- Rice Husk Fired Steam Boiler

- Industrial Steam Boiler

- Husk Fired Boiler

- Wood Fired Boiler

- Oil Fired Steam Boiler

- Oil Fired Boiler

- Reverse Flow Steam Boiler

- Package Boiler

- Fire Steam Boilers

- SIB Steam Boiler

- Smoke tube Package Steam Boiler

- Solid Fuel Fired 10 TPH Water Wall Membrane Panel Steam Boiler

- Coconut Shell Fired 5000 Kg-hr Steam Boiler

- Nutshell Fired 4 TPH Fully Wetback Steam Boiler

- 2 TPH Electric Steam Boiler

- Coal Fired 3 TPH Fully Wetback Steam Boiler

- Thermic Fluid Heater

- Heat Exchanger

- Bag Filter

- Industrial Boiler

- Solid Fuel Boiler

- Industrial Steam Boiler

- Boiler

- FBC Boilers

- Wood Fired Steam Boilers

- Glass Smoking Pipes

- Oil Fired Steam Boiler

- Coconut Shell Fired 3000 Kg-hr Steam Boiler

- Oil And Gas Fired 500-1000 Kg-hr 3 Pass Wet Back Boiler IBR Approved

- Oil & Gas Fired 3000 Kg-hr Fully Wetback Steam Boiler IBR Approved

- Oil & Gas Fired 8000 Kg-hr Fully Wetback Steam Boiler IBR Approved

- Oil & Gas Fired 50 kg-hr Coil Type Steam Boiler Non-IBR

- Oil Fired Heaters

- Pulse Jet Bag Filter

- Steam Boiler

- Contact Us

Vertical Thermic Fluid Heater

1250000 INR/Unit

Product Details:

- Condition New

- Voltage 220/380/415V, 3 Phase, 50/60 Hz

- Heat Efficiency Up to 85%

- Life Span 10-15 Years

- Capacity 0.2 to 10 million kcal/hr

- Style Vertical

- Fuel Type Coal, Oil, Gas, Biomass

- Click to view more

X

Vertical Thermic Fluid Heater Price And Quantity

- 1250000 INR/Unit

- 1 Unit

- Continuous/Duty Cycle

- As per statutory and site requirements

- Floor Mounted

- Manual / Automatic

- Auto/Manual ignition for oil/gas models

- Compatible (optional accessory)

- Digital Temperature Controller & Indicator

- Safety Valve, Pressure Switch, Temperature Limit Switch

- Industrial Grey / Custom Paint

- Process Heating in Textile, Chemical, Oil, Food, and Pharma industries

- Available

- Glass Wool / Mineral Wool with Aluminum Cladding

Vertical Thermic Fluid Heater Product Specifications

- Vertical Thermic Fluid Heater

- Depends on model and fuel type, typically 15-50 kg/hr (solid), 12-40 L/hr (liquid)

- Customizable as per requirement

- Mild Steel / Carbon Steel

- Thermic Fluid Heated Stream

- Up to 350C

- Atmospheric / Low Pressure

- 10-15 Years

- Up to 85%

- 220/380/415V, 3 Phase, 50/60 Hz

- New

- Heat Transfer using Thermic Fluid

- Coal, Oil, Gas, Biomass

- 0.2 to 10 million kcal/hr

- Vertical

- Continuous/Duty Cycle

- As per statutory and site requirements

- Floor Mounted

- Manual / Automatic

- Auto/Manual ignition for oil/gas models

- Compatible (optional accessory)

- Digital Temperature Controller & Indicator

- Safety Valve, Pressure Switch, Temperature Limit Switch

- Industrial Grey / Custom Paint

- Process Heating in Textile, Chemical, Oil, Food, and Pharma industries

- Available

- Glass Wool / Mineral Wool with Aluminum Cladding

Vertical Thermic Fluid Heater Trade Information

- 10 Unit Per Day

- 60 Days

Product Description

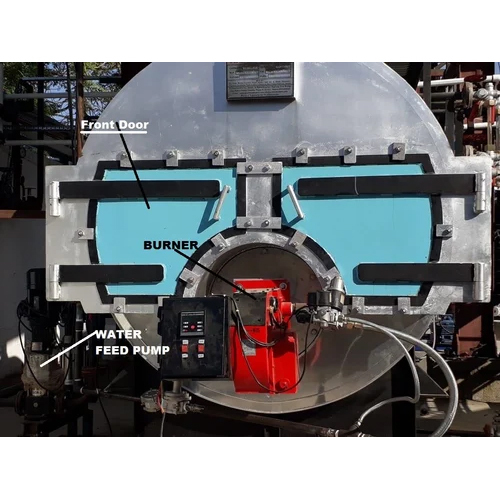

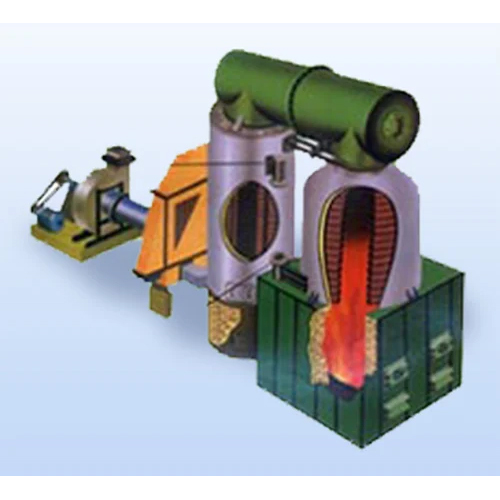

Vertical Thermic Fluid Heater is a solid fuel fired heating plant that is used for energy generation in various industries. This is widely demanded by our customers for their ease in operation, they have sophisticated controls for the organized handling of fuel and ash. Made of the best quality mild steel, this machine is resistant to rust, corrosion, high temperatures, adverse industrial pressure, etc. We provide Vertical Thermic Fluid Heater in different specifications according to the needs of the customers

Reliable and Versatile Process Heating

Our vertical thermic fluid heater delivers consistent, efficient heat transfer tailored for industrial operations in textiles, chemicals, oils, food, and pharmaceuticals. The system is engineered for flexibility, supporting various fuels and firing modes to ensure optimal performance and adaptability for diverse production environments.

Advanced Safety and Control Systems

Safety and control are integral to our heaters design. Equipped with safety valves, pressure switches, and temperature limiters, the system offers peace of mind during operation. The digital temperature controller and indicator provide precise monitoring, supporting process integrity and operator safety in demanding industrial settings.

Customized Construction and Superior Insulation

Fabricated in mild or carbon steel, the heaters dimensions, paint finish, and mounting are fully customizable. Its insulationglass wool or mineral wool with aluminum claddingalong with a pre-insulated body option, maximize thermal retention, ensuring energy-efficient, reliable, and long-lasting performance.

FAQs of Vertical Thermic Fluid Heater:

Q: How does the vertical thermic fluid heater improve process heating efficiency in industrial applications?

A: The heater employs high-efficiency heat transfer capabilities, reaching up to 85% thermal efficiency. Its advanced insulation reduces energy losses, while the digital temperature control system maintains optimal and consistent heating, critical for processes in textile, chemical, oil, food, and pharma sectors.Q: What safety mechanisms are integrated into the vertical thermic fluid heater for industrial use?

A: Integrated safety features include a safety valve, pressure switch, and temperature limit switch. These mechanisms prevent overpressure and overheating, ensuring safe operation even during continuous or duty cycle processes. The digital temperature indicator further alerts operators to real-time temperature changes.Q: When should the circulation pump be used with this thermic fluid heater?

A: A compatible circulation pump is recommended when continuous movement of thermic fluid is necessary, especially in large-scale or complex process heating setups. This ensures uniform fluid temperature and effective heat distribution throughout the system.Q: Where is the preferred installation site for a vertical thermic fluid heater?

A: The heater is designed for floor-mounted installation, typically positioned in process plants or industrial utility areas. Chimney height and location are customized based on statutory requirements and site specifics to ensure optimal exhaust and safety.Q: What is the operational process for the heaters manual and automatic firing modes?

A: Manual firing requires operator intervention for fuel ignition, suitable for basic process needs. Automatic firing features programmable ignition and control for oil/gas models, enabling seamless, safe, and efficient operation, particularly in continuous or scheduled duty cycles.Q: How does insulation material benefit the heaters performance?

A: The use of glass wool or mineral wool insulation, clad in aluminum, significantly minimizes thermal loss from the heater body. Pre-insulated heater models further amplify energy efficiency, leading to reduced fuel consumption and lower operating costs.Q: What are the advantages of customizing the vertical thermic fluid heaters dimensions and configuration?

A: Customized dimensioning allows integration into unique plant layouts and process requirements. This adaptability, coupled with options for paint, mounting, and fuel type, ensures the heater fits seamlessly into varied industrial environments, optimizing both space utilization and performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese